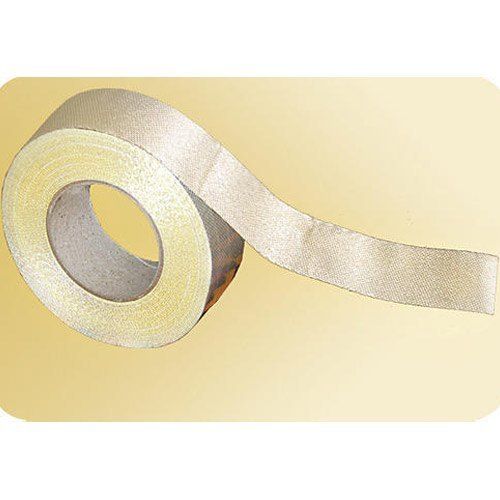

Kapton Polyimide Tape

Kapton Polyimide Tape Specification

- Coating Type

- Silicone adhesive

- Thermal Conductivity

- 0.12 W/mK

- Density

- 1.42 Gram per cubic centimeter(g/cm3)

- Usage & Applications

- High temperature electrical insulation, wave soldering masking, 3D printing bed surface

- Temperature

- -73C to +260C

- Shape

- Roll

- Application

- Insulation, PCB masking, capacitor wrapping, lithium battery manufacturing

- Technique

- Pressure Sensitive Adhesive (PSA)

- Surface Treatment

- Silicone coated

- Dimension (L*W*H)

- 33 m (Length) x up to 500 mm (Width)

- Flame Retardant

- UL-94 V-0

- Storage Condition

- Cool, dry place, away from direct sunlight

- Water Absorption

- <3% after 24 hours

- Electrical Resistance

- >10^16 cm

- Tensile Strength

- 42 N/10mm

- Elongation at Break

- 45%

- Dielectric Strength

- >6500 V

Kapton Polyimide Tape Trade Information

- Minimum Order Quantity

- 10 Rolls

- Payment Terms

- Cash Advance (CA), Cheque, Cash in Advance (CID)

- Supply Ability

- 50 Rolls Per Day

- Delivery Time

- 2-3 Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Box Packing

- Main Export Market(s)

- Asia, Middle East, Western Europe, South America, Australia, North America, Central America, Eastern Europe, Africa

- Main Domestic Market

- All India

About Kapton Polyimide Tape

Applications:

- Automotive sensor and manifolds

- Insulating circuit boards

- Etching

- Fiber Optics Cable

- High temperature powder coating

- Semiconductor manufacturing

- Wave soldering during circuit board assembly

Specification

| Material | Kapton HN Film |

| Usage/Application | Industrial Purpose |

| Temperature | -269 DegreeC To 260 DegreeC |

| Color | Brown |

| Pattern | Plain |

| Total Thickness | 1 Mil |

| Adhesive Type | Silicone Adhesive |

| Brand | Kapton |

| Type | Single Sided |

| Surface Finsh | Shiny |

| Size | 1/8" x 36 yds |

| Part Number | KPT-1/8 |

| Packaging Type | Roll |

Exceptional Performance in Extreme Conditions

This Kapton Polyimide Tape exhibits remarkable resilience in environments ranging from sub-zero to high temperatures, thanks to its wide operating range of -73C to +260C. Its flame-retardant and high dielectric strength qualities make it indispensable for electronics, aerospace, and industrial applications that require dependable insulation even under harsh conditions.

Advanced Electrical and Mechanical Properties

Specially formulated for outstanding electrical resistance and mechanical strength, the tape features a dielectric strength over 6500 V and impressive elongation at break of 45%. Its density of 1.42 g/cm and low thermal conductivity ensure reliable performance in high-voltage and heat-sensitive environments.

Versatile Applications Across Industries

Kapton Polyimide Tapes pressure-sensitive silicone adhesive enables excellent adherence to varied surfaces. Commonly used for PCB masking during soldering, capacitor wrapping, lithium battery manufacturing, and as a bed surface in 3D printing, it suits numerous advanced industrial uses, from prototyping to large-scale electronics production.

FAQs of Kapton Polyimide Tape:

Q: How should Kapton Polyimide Tape be applied for optimal performance?

A: Ensure the surface is clean and dry. Unwind the roll, position the tape on the desired area, and press it firmly using moderate pressure to activate the pressure-sensitive silicone adhesive. This guarantees strong adhesion and effective insulation.Q: What benefits does the high dielectric strength offer in electronic applications?

A: With a dielectric strength greater than 6500 V, Kapton Polyimide Tape provides robust electrical insulation, protecting sensitive electronic components from voltage breakdown or shorts, especially during PCB fabrication and wave soldering processes.Q: When and where is Kapton Polyimide Tape most commonly used?

A: The tape is frequently used in industries requiring thermal and electrical insulation, such as electronics manufacturing, 3D printing, lithium battery assembly, and capacitor fabrication. Its temperature tolerance and flame retardancy make it suitable for both standard and harsh environments.Q: What process is used for producing the adhesive side of the tape?

A: The tape utilizes a pressure-sensitive adhesive (PSA) process, where a silicone-based adhesive is evenly coated onto one side of the polyimide film, creating a durable, single-sided adhesive suitable for high-temperature and high-stress environments.Q: How does the tapes flame retardant feature benefit industrial safety?

A: Kapton Polyimide Tape is rated UL-94 V-0 for flame retardancy, meaning it stops burning within 10 seconds on a vertical specimen. This significantly reduces fire hazards, making it a safer option in electrical and electronic assemblies.Q: What storage conditions are ideal for maintaining tape quality?

A: To preserve adhesive and material integrity, store the tape in a cool, dry place, away from direct sunlight and sources of moisture. Proper storage ensures long shelf life and consistent performance when used.Q: Can Kapton Polyimide Tape be used for masking during wave soldering?

A: Yes, its excellent chemical stability, thermal resistance, and electrical insulation make it particularly effective as a protective mask for PCBs during wave soldering, preventing solder from contacting covered areas.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heat Resistant Tape Category

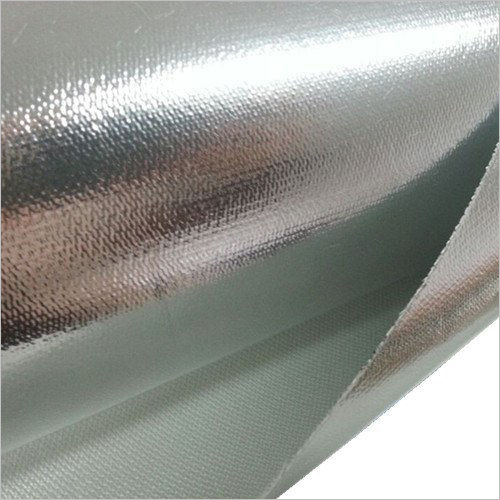

High Silica Tapes

Price 1450 INR / Piece

Minimum Order Quantity : 10 Rolls

Thickness : 0.75 Millimeter (mm)

Adhesive : Other

Material : Other

Length : 10 Meter (m)

PTFE Glass Adhesive Tape

Price 70 INR / Roll

Minimum Order Quantity : 50 Rolls

Thickness : 0.15 Millimeter (mm)

Adhesive : Other

Material : Other

Length : 10 Meter (m)

PTFE Glass Cloth Adhesive Tape

Price 100.00 INR / Roll

Minimum Order Quantity : 50 Rolls, ,

Thickness : 0.15 Millimeter (mm)

Adhesive : Other

Material : Other

Length : 10 Meter (m)

Fiberglass Woven Tape

Minimum Order Quantity : 50 Rolls

Thickness : 1 Millimeter (mm)

Adhesive : Other

Material : Other

Length : 30, 50 Meter (m)

|

SHREE SHYAM CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry