Most Popular Products

Fiberglass Woven Roving Tape

Fiberglass Woven Roving Tape Specification

- Temperature

- -50C to 550C

- Thickness

- 0.15mm to 0.45mm

- Thermal Conductivity

- Low, approx. 1 W/mK

- Usage & Applications

- Laminating, repairs, structural reinforcement, FRP manufacturing

- Shape

- Tape, rectangular

- Density

- 2.6 Gram per cubic centimeter(g/cm3)

- Glass Type

- E-Glass

- Coating Type

- None or customized epoxy compatible

- GSM

- 200gsm, 300gsm, 400gsm, 600gsm, 800gsm, per requirement

- Material

- E-glass fiberglass

- Application

- Reinforcement for composite materials, boat building, automotive, aerospace, construction

- Technique

- Woven

- Surface Treatment

- Silane or customized

- Dimension (L*W*H)

- Customizable, commonly 50mm/100mm/150mm width, roll length up to 100m

About Fiberglass Woven Roving Tape

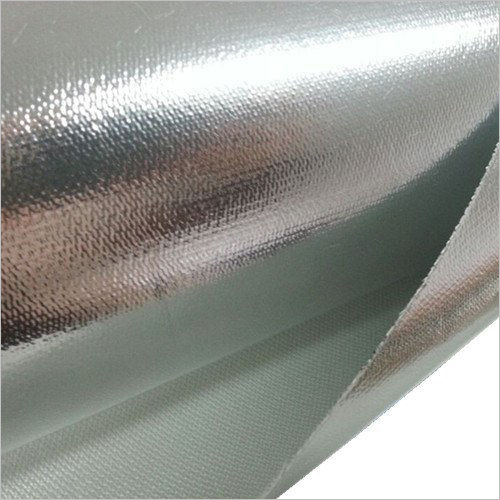

Fiberglass woven roving tape is necessarily used in marine, automotive industries. It's usage also boosts the growth of aerospace industry. This tape has been significantly made using quality assured fiber glass strands. It is certainly a reliable tape that has good adhesive features. Fiber glass woven roving tape is incredibly strong and possesses different properties including chemical resistance and thermal insulation. It is widely utilized in construction and sports industry, owing to the extended durability. Our qualitative product fully gratifies the exact needs and demands of valuable customers.

Superior Structural Reinforcement

Fiberglass Woven Roving Tape enhances the structural integrity of composite constructions. With high tensile strength and excellent corrosion resistance, it is commonly used for laminating, repairs, and structural reinforcement in marine, automotive, and aerospace industries. Its compatibility with multiple resins ensures versatile usage across many composite applications.

Customizable Solutions for Every Project

This woven tape is available in customizable lengths and widths (typically 50mm, 100mm, 150mm, up to 100m per roll), making it easy to adapt to your specific project requirements. Different GSM weights (200, 300, 400, 600, 800gsm) and surface treatments, including silane, provide further flexibility for specialized applications.

Reliable Performance in Extreme Environments

Engineered for reliable operation, this tape withstands temperatures from -50C to 550C. Its low thermal conductivity and moisture content make it particularly suited to environments where heat or humidity could compromise other materials. Plus, with its non-combustible nature, it adds critical fire resistance to any structure.

FAQs of Fiberglass Woven Roving Tape:

Q: How is fiberglass woven roving tape typically used in composite manufacturing?

A: Fiberglass woven roving tape functions as a reinforcement layer, providing strength and stability during the fabrication of composite materials. It is laminated with polyester, epoxy, or vinyl ester resins to construct or repair components in marine, automotive, aerospace, and construction applications.Q: What are the benefits of using fiberglass woven roving tape with E-glass?

A: E-glass fibers offer excellent corrosion resistance, high tensile strength, and low elongation at break (<4%). These properties, combined with its non-combustible nature and low thermal conductivity, provide durability and protection for reinforced structures.Q: When should I use plain versus twill weave patterns?

A: Plain weave is best for applications requiring consistent thickness and uniform strength, while twill weave provides better drapability and conformability for complex shapes. The choice depends on the projects shape and mechanical requirements.Q: Where can I apply this tape for optimal results?

A: This tape is ideal for use in structural reinforcement projects, boat hull laminations, vehicle panel repairs, aerospace component manufacturing, FRP tanks, and general construction.Q: What is the process for applying fiberglass woven roving tape with resin?

A: Cut the tape to the desired length, lay it onto the prepared substrate, and saturate with compatible resin (polyester, epoxy, or vinyl ester). Use a roller to remove air bubbles and ensure complete adhesion. Allow curing as specified by the resin manufacturer.Q: Is the tape suitable for high-temperature or corrosive environments?

A: Yes, the tape is designed for sustained performance in temperatures from -50C to 550C and offers excellent resistance to corrosion, making it suitable for harsh chemical and thermal conditions.Q: What are the standard packaging and available roll sizes?

A: Fiberglass woven roving tape is typically packaged in rolls wrapped with plastic film or shipped in cartons. Standard roll lengths are 50 meters, but customization up to 100 meters and various widths (commonly 50mm/100mm/150mm) are available.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fiberglass Woven Roving Tape Category

|

SHREE SHYAM CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry